There's an old hot rod suspension trick,

grafting the front radius rod ball from a 30's Ford,

on to the rear arms.

I love the idea reusing the old parts,

but over the past 10 years there has been constant upkeep.

I've gone through a couple of the rubber balls that cover the pivot ball,

and the cast housing had cracked.

Instead of continuing the fight,

another variation has been brewing to locate the rear end,

retaining the theme of reusing front end parts.

I had used this idea on the rusty 40 coupe.

Using a 60's chevy ball joint.

It seems strong but I wish I had put it upside down,

so the weight of the body would push up the ball joint.

Chief's (1929 roadster pickup) rear suspension was perfect for this conversion.

The ball was quickly hacked off.

I had visualized a triangular plate,

but forgot the template when I went back to the shop.

It took a long time to file out the angled hole.

The chevy version uses a 1/2" nut,

and the ford version uses a 9/16" nut,

on a 5/8"(start) tapered shaft.

Much stronger.

Oh yeah,

another thing I had to do was redrill the stud for a closer cotter pin,

cutting the post down almost about half an inch.

Back in the garage,

the locater hole only needed to be enlarged a little bit.

I was lucky that the original housing used a similar hole.

After alot of drilling and filing,

the ball joint was finally installed.

There's a little play just in case it needs to be tuned up,

not because it was getting late and I was in a rush,

working on my back in a pile of metal shavings,

while the kids were starving so I was also cooking spaghetti,

since they were too busy building models.

With the ball joint centered,

and the kids fed,

the new bracket was trimmed to fit.

Since this was home garage work,

I had to stick weld it on.

It passed the hammer test.

After some wire brushing to remove the flux,

some rattle can was sprayed on the hot metal.

It really bakes it on.

After years of trying to limit the old pickup to 1940's technology,

it is time to test this 1960's upgrade.

I've put alot of thought into this,

and figure the old pivot housing was located with 2 bolts,

and the ball joint with 3.

The old pivot housing was cast,

the ball joint (i think) is forged.

They both use a large locating hole to keep them centered,

so if something breaks the housing is still secure.

Also,

the thickness of the ball joint shaft,

is about the same as the attachment post of the old pivot ball.

The main thing is to keep tabs on it.

The pivot seems rock solid,

just like a spindle in an A-arm.

The suspension only has a couple inches travel,

so the ball joint won't have radical movement.

The transverse rear spring also really limits any front or side to side play.

If anything,

I can always trade up from this $13 ball joint to the $40 version.

Time will tell!

TP

grafting the front radius rod ball from a 30's Ford,

on to the rear arms.

|

| traditional rear suspension |

I love the idea reusing the old parts,

but over the past 10 years there has been constant upkeep.

I've gone through a couple of the rubber balls that cover the pivot ball,

and the cast housing had cracked.

|

| repaired 1936 ford housing |

Instead of continuing the fight,

another variation has been brewing to locate the rear end,

retaining the theme of reusing front end parts.

|

| modified rear suspension |

I had used this idea on the rusty 40 coupe.

Using a 60's chevy ball joint.

It seems strong but I wish I had put it upside down,

so the weight of the body would push up the ball joint.

|

| chief's old suspension |

Chief's (1929 roadster pickup) rear suspension was perfect for this conversion.

|

| surgery |

The ball was quickly hacked off.

|

| template |

I had visualized a triangular plate,

but forgot the template when I went back to the shop.

|

| 1968 ford mustang ball joint |

It took a long time to file out the angled hole.

The chevy version uses a 1/2" nut,

and the ford version uses a 9/16" nut,

on a 5/8"(start) tapered shaft.

Much stronger.

Oh yeah,

another thing I had to do was redrill the stud for a closer cotter pin,

cutting the post down almost about half an inch.

|

| donkey dick |

Back in the garage,

the locater hole only needed to be enlarged a little bit.

I was lucky that the original housing used a similar hole.

|

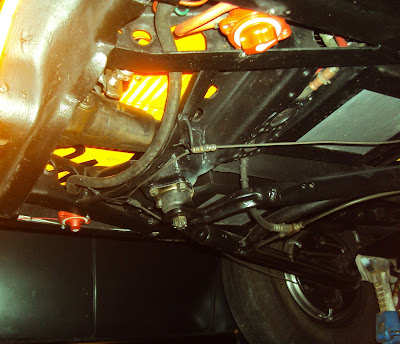

| ball joint installed |

After alot of drilling and filing,

the ball joint was finally installed.

There's a little play just in case it needs to be tuned up,

not because it was getting late and I was in a rush,

working on my back in a pile of metal shavings,

while the kids were starving so I was also cooking spaghetti,

since they were too busy building models.

|

| welded |

With the ball joint centered,

and the kids fed,

the new bracket was trimmed to fit.

Since this was home garage work,

I had to stick weld it on.

It passed the hammer test.

|

| trippy engineering |

After some wire brushing to remove the flux,

some rattle can was sprayed on the hot metal.

It really bakes it on.

|

| updated rear suspension |

After years of trying to limit the old pickup to 1940's technology,

it is time to test this 1960's upgrade.

I've put alot of thought into this,

and figure the old pivot housing was located with 2 bolts,

and the ball joint with 3.

The old pivot housing was cast,

the ball joint (i think) is forged.

They both use a large locating hole to keep them centered,

so if something breaks the housing is still secure.

Also,

the thickness of the ball joint shaft,

is about the same as the attachment post of the old pivot ball.

|

| hot rod rear suspension |

The main thing is to keep tabs on it.

The pivot seems rock solid,

just like a spindle in an A-arm.

The suspension only has a couple inches travel,

so the ball joint won't have radical movement.

The transverse rear spring also really limits any front or side to side play.

If anything,

I can always trade up from this $13 ball joint to the $40 version.

Time will tell!

TP

No comments:

Post a Comment