Months ago I had started the set up of the independent corvette rearend on the '56 chevy truck frame.

It was trickier than I had expected.

First I tried to simulate a loaded frame so stuffed a bunch of heaviness on the frame.

I realized quickly that the frame would need to be notched.

I'm not a big fan of notches so figured a kicked up frame would flow better.

More importantly, this would also keep the bed floor flat.

The frame didn't need alot of tweaking, only about 1.5" higher.

Reloaded with weight, the frame was level.

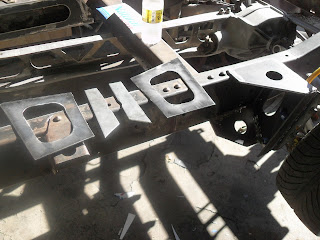

The next course of action was to make some cups to hold the stock rearend hangers.

All that is needed is a left and right cup to wedge in the trapezoidal insert.

This is the main piece that locates the rearend to the frame,

while supporting all the rear weight!

This was the tricky part.

The 85 corvette uses a carbon fiber transverse rear spring that is behind the axle/driveshafts,

so when there is a load, it kicks up the 4-link bracket above the framerails, like the picture.

Fortunately I took measurements off the old corvette frame,

and was able to adjust the pivot point by simply jacking up the rear of the axle housing.

Now the angles were the same as the corvette.

When bouncing the loaded rearend, the travel seemed real smooth.

After making all the major brackets and gussets out of 1/4" plate,

everything was welded up,

strong enough to finish up other parts of the frame, but not finished,

just in case something needed changing.

This is how it sat for a couple months while other stuff was done.

Every time someone saw it I'd have to tell them the same "work in progress" excuse,

since it was ugly and unknowingly to some incomplete.

The plan was to finish the frame front to back.

After boxing the middle of the frame,

this week the rearend could finally be completed.

After making some templates, Luke cut them out for me.

I was impressed he did such a good job.

This was all out of 3/16" steel plate.

Things are good when both sides match!

Welded everything up with the trusty MIG...

And since Ken wants a show car and I like grinding...

I was relieved that it matched what I was imagining it too look like.

Had to make these little pieces for the bottom too,

but didn't take a pic of them installed.

Also whipped out the top shock mounts,

still might gusset the top,

but this will have to wait til the rearend is dropped out,

when all the hard to reach grinding/welding will get done,

like on that rear cup!

There is so much more work on this thing,

but at least its a solid rolling frame at this point,

and Ken is happy!

I'm hoping this is going to be one bad ass all chevrolet truck!

TP

It was trickier than I had expected.

|

| loaded |

First I tried to simulate a loaded frame so stuffed a bunch of heaviness on the frame.

I realized quickly that the frame would need to be notched.

|

| kickup start |

I'm not a big fan of notches so figured a kicked up frame would flow better.

More importantly, this would also keep the bed floor flat.

|

| boxing plates |

The frame didn't need alot of tweaking, only about 1.5" higher.

|

| reloaded |

Reloaded with weight, the frame was level.

|

| cups |

The next course of action was to make some cups to hold the stock rearend hangers.

All that is needed is a left and right cup to wedge in the trapezoidal insert.

This is the main piece that locates the rearend to the frame,

while supporting all the rear weight!

|

| sprung |

This was the tricky part.

The 85 corvette uses a carbon fiber transverse rear spring that is behind the axle/driveshafts,

so when there is a load, it kicks up the 4-link bracket above the framerails, like the picture.

Fortunately I took measurements off the old corvette frame,

and was able to adjust the pivot point by simply jacking up the rear of the axle housing.

|

| jacked |

Now the angles were the same as the corvette.

When bouncing the loaded rearend, the travel seemed real smooth.

|

| garage engineered |

After making all the major brackets and gussets out of 1/4" plate,

everything was welded up,

strong enough to finish up other parts of the frame, but not finished,

just in case something needed changing.

|

| hiatus |

This is how it sat for a couple months while other stuff was done.

Every time someone saw it I'd have to tell them the same "work in progress" excuse,

since it was ugly and unknowingly to some incomplete.

The plan was to finish the frame front to back.

After boxing the middle of the frame,

this week the rearend could finally be completed.

|

| boxed |

After making some templates, Luke cut them out for me.

I was impressed he did such a good job.

This was all out of 3/16" steel plate.

|

| transformers |

Things are good when both sides match!

Welded everything up with the trusty MIG...

|

| welded |

And since Ken wants a show car and I like grinding...

|

| smoothy |

I was relieved that it matched what I was imagining it too look like.

Had to make these little pieces for the bottom too,

but didn't take a pic of them installed.

|

| bottom pieces |

Also whipped out the top shock mounts,

still might gusset the top,

but this will have to wait til the rearend is dropped out,

when all the hard to reach grinding/welding will get done,

like on that rear cup!

|

| finally |

There is so much more work on this thing,

but at least its a solid rolling frame at this point,

and Ken is happy!

I'm hoping this is going to be one bad ass all chevrolet truck!

TP

No comments:

Post a Comment